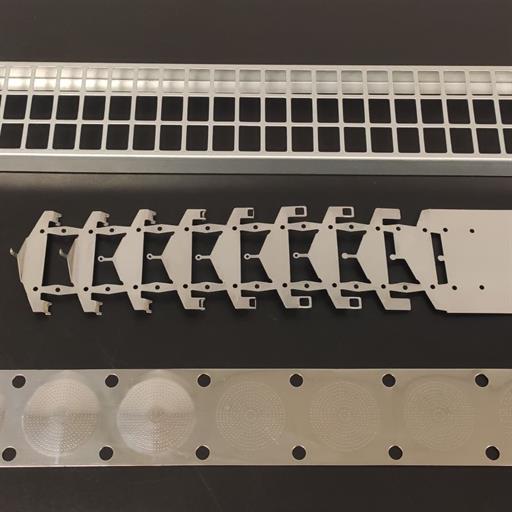

MOLDING OF FERROUS MATERIALS AND PLASTIC MATERIALS

Molding is the production method par excellence when we talk about large series of parts as it guarantees high speed while maintaining continuous dimensional stability over time and maximum optimization of material consumption.The molds are mostly made internally or upon request provided by the customer. For production we can start from coils, sheet metal or squares.

Through presses of different tonnages, up to 300 tons, connected to unwinders we can carry out shearing, bending, drawing and bending of ferrous and non-ferrous materials.

The company has been collaborating for several years now, with two companies specialized in the molding of plastic materials with which we have established an ongoing and constant relationship. The injection machine fleet ranges from 40 to 1500 tons.

This allows us to integrate not only the creation of the mold but the subsequent molding of the components into the offer.

Powered by Passepartout

Designed by Passepartout & Delta System

Designed by Passepartout & Delta System